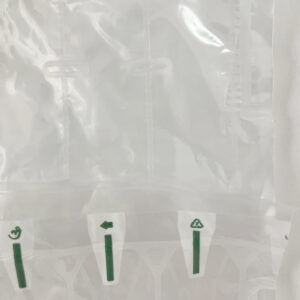

Air column bag

Air column bags, also known as cushioning air column bags and inflatable bags, are new packaging materials filled with natural air in the 21st century. Made of high-quality PE+PA film and advanced technology, they have good toughness, air tightness and cushioning properties.

1: Custom shape bag: Our factory can make design customized bag depend on your products, like bottle, we will design Q shape bag for you; milk power, we will design L shape bag for you; like plants, we will design U shape bag.

2: Make bag in rolls : We can sale bags in rolls, you can order our bags in pieces or in rolls.

3: Connect bag: We can make single bag, double bag or three connected bags and so on.

Product name | Air column bag, air cushion bag, inflate air column package bag |

Material | PE+PA(20% Nylon) |

Specification | Accept Customized size/logo/colour, different products’ size bag , we can produce it . |

Application | Wine bottle, jade ware, lamp,cosmetics, camera and other fragile products |

Number of air columns | List air column bags of different specifications, such as 5 columns, 6 columns, 7 columns, etc. |

Air column diameter | Corresponding to the number of air columns, explain the diameter range of the air columns, such as 5 – 6cm, 6 – 7cm, etc. |

Suitable height | Detailed description of the height range of each specification of air column bag suitable for packaging items, such as 10 – 12cm, 13 – 14cm, etc. |

Other products | Air cushion bubble film , air column bag, air column roll and so on. |

Q: How to inflate the air column bag?

A: Use a mini electric air pump for a small quantity of bags. For rolled bags, use a special inflator. Connect the air valve to the inflator and start for quick inflation.

A: Use a mini electric air pump for a small quantity of bags. For rolled bags, use a special inflator. Connect the air valve to the inflator and start for quick inflation.

Q: Can it be reused?

A: Yes, if undamaged. Check its airtightness and condition before reuse.

A: Yes, if undamaged. Check its airtightness and condition before reuse.

Q: What if it’s damaged during transportation?

A: A single damaged air column usually won’t affect product safety. For serious damage, contact our after-sales team for solutions.

A: A single damaged air column usually won’t affect product safety. For serious damage, contact our after-sales team for solutions.